that was a pleasure to watch sir!!!jmadrigal wrote: Made a short video for the latest project. I call her Seven. I am going to make a few more pushing the weight around. She weighs in at 184gm. It's a bit of a mashup of my past two designs. The machine has a better time printing the wider flat shoulders. I think it also feel more stable.

https://youtu.be/w3gdQCYDkV8

3D Printed Top

Re: 3D Printed Top

Re: 3D Printed Top

jmadrigal wrote: This weekends work. Lots of time hereI estimate over 50 hours in print time.

The large orange top is the latest. 177gm and 4.6" in diameter. I am happy with this shape. It's very playable and stable.

Out of curiosity what do wood tops of this size usually weigh?

The smaller tops are a similar shape shrunk down the orange one with the tip is 84gm and 3" in diameter. I am using the Quicksilver tip pressed in. The grey one with the tip only weighs 44gm and is 2.9" in diameter. It is a very light tip since I used very thin walls. It is also a testament to the ABS strength since I beat the tip in with a mallet.

On the orange one with the tip, I placed the tip in as soon as the top was done and still hot. When the top cooled and shrunk a bit the tip was in tight. I was quite by chance this happened but it was neat.

Last edited by Jack on Tue Nov 08, 2016 8:59 am, edited 1 time in total.

Re: 3D Printed Top

The tip I used is from the Spintastics Quicksilver top. I have also used the YYF metal replacement tips on others. I am not really a fan of plastic tips.yoyospin wrote: Have a look at the metal and plastic tips Spintastics sells. I've used hundreds of their injection molded plastic ones. They are very consistantly made: http://www.spintastics.com/spin-tops/

Re: 3D Printed Top

Confucius say: metal tip is best tip @-@jmadrigal wrote: I am not really a fan of plastic tips.

Re: 3D Printed Top

I took old tip out of top and put it into my son in laws top. So this is the new one. I will get the dimensions.

- Attachments

-

- FIGHTER -- BEST IN THE WORLD 006.jpg (46.81 KiB) Viewed 2591 times

-

- FIGHTER -- BEST IN THE WORLD 004.jpg (55.6 KiB) Viewed 2589 times

-

- FIGHTER -- BEST IN THE WORLD 001.jpg (43.74 KiB) Viewed 2591 times

Re: 3D Printed Top

Looks good cecil. How much does a top like that weigh? I am trying to figure out how my printed tops compare to similar size wood tops.

Re: 3D Printed Top

beautifulcecil wrote: I took old tip out of top and put it into my son in laws top. So this is the new one. I will get the dimensions.

Re: 3D Printed Top

In Spanish by myself:

He entrado por primera vez en el foro desde hace muchísimo tiempo pues tenía curiosidad si la impresión 3 D, en la que estoy interesado hace tiempo había llegado ya a este mundo del trompo.

Estoy viendo en Pinterest tantas cosas maravillosas e increíbles hechas en impresión 3D que mucho me hubiera extrañado si no hubiera nada.

Pero me interesa también la tecnología que hay tras los maravillosos trompos que he visto en este hilo. Como cómo se hacen los diseños, si se escanea en 3D o se modela con un programa de ordenador y ver a la propia impresora en acción, o de cómo es el proceso completo, para que podamos irnos introduciendo también.

Es un mundo enorme y hay bastantes tipos de impresión 3D y materiales.

Atesoro el prototipo hecho en impresión 3D del prototipo de la Saturno, de Trompos Space. Supongo que seguirá siendo proceso previo a la producción crear un prototipo de cada trompo en impresión 3D para testar fácil el correcto funcionamiento.

In english with google traslator:

I have first entered the forum for a very long time because I was curious if the 3 D impression, in which I have been interested for a long time, has already reached this spinning world.

I am seeing in Pinterest so many wonderful and incredible things made in 3D printing that I would have missed a lot if there was nothing.

But I'm also interested in the technology behind the wonderful spins I've seen in this thread. How to make the designs, whether it is 3D scan for model with a computer program and see the printer itself in action, or how the process is complete, so we can introduce ourselves as well.

It's a huge world and there are quite a few types of 3D printing and materials.

I treasure the prototype made in 3D printing of the prototype of Saturn, from Space Trompos. I guess it will continue to be the pre-production process to create a prototype of each top in 3D printing to easily test the correct operation.

He entrado por primera vez en el foro desde hace muchísimo tiempo pues tenía curiosidad si la impresión 3 D, en la que estoy interesado hace tiempo había llegado ya a este mundo del trompo.

Estoy viendo en Pinterest tantas cosas maravillosas e increíbles hechas en impresión 3D que mucho me hubiera extrañado si no hubiera nada.

Pero me interesa también la tecnología que hay tras los maravillosos trompos que he visto en este hilo. Como cómo se hacen los diseños, si se escanea en 3D o se modela con un programa de ordenador y ver a la propia impresora en acción, o de cómo es el proceso completo, para que podamos irnos introduciendo también.

Es un mundo enorme y hay bastantes tipos de impresión 3D y materiales.

Atesoro el prototipo hecho en impresión 3D del prototipo de la Saturno, de Trompos Space. Supongo que seguirá siendo proceso previo a la producción crear un prototipo de cada trompo en impresión 3D para testar fácil el correcto funcionamiento.

In english with google traslator:

I have first entered the forum for a very long time because I was curious if the 3 D impression, in which I have been interested for a long time, has already reached this spinning world.

I am seeing in Pinterest so many wonderful and incredible things made in 3D printing that I would have missed a lot if there was nothing.

But I'm also interested in the technology behind the wonderful spins I've seen in this thread. How to make the designs, whether it is 3D scan for model with a computer program and see the printer itself in action, or how the process is complete, so we can introduce ourselves as well.

It's a huge world and there are quite a few types of 3D printing and materials.

I treasure the prototype made in 3D printing of the prototype of Saturn, from Space Trompos. I guess it will continue to be the pre-production process to create a prototype of each top in 3D printing to easily test the correct operation.

Re: 3D Printed Top

Pulp

I think you are asking me the process I use for making/designing my tops. I use a 3D cad program to draw what I want to print. For simple things like tops, Google SketchUp is free and works fine. When you have made your drawing you need to generate a .stl file for your project. SketchUp does not do this directly but you can download an extension that will do this for you. Once you have your .stl file you upload it to your slicer software that lets you control how your print will be built. Here you select part print orientation, fill %, layer height, speed, temperature, support material and more. After this you ready to print.

From my experience machines vary wildly in quality. These machines are for people who like to tinker and usually won't give good prints without some work. Printers are getting better, but still need a lot of attention. For most consumer machines in the ~$500 range, I would expect to put in a lot of time leveling the bed and working about your part lifting during the print.

As far as materials go, there are a lot of options. PLA is simple to print and does not require a heated bed but is not as durable as the other materials. ABS is strong but requires a heated bed and tends to have shrinkage/warping problems, so you have to design accordingly. Polycarbonate is impact resistant and strong but requires a nozzle that can print at over 300 C. Nylon is tough and would also be a good option but also requires higher nozzle temperatures. There are many other materials, these are just some of the common ones.

I think printing is definitely worth the time. I recently checked how much one of my 3" tops would cost through Shapeways. They quoted me over $200 for an ABS print. I think my machine is paying for it's self each time I make a top.

I think you are asking me the process I use for making/designing my tops. I use a 3D cad program to draw what I want to print. For simple things like tops, Google SketchUp is free and works fine. When you have made your drawing you need to generate a .stl file for your project. SketchUp does not do this directly but you can download an extension that will do this for you. Once you have your .stl file you upload it to your slicer software that lets you control how your print will be built. Here you select part print orientation, fill %, layer height, speed, temperature, support material and more. After this you ready to print.

From my experience machines vary wildly in quality. These machines are for people who like to tinker and usually won't give good prints without some work. Printers are getting better, but still need a lot of attention. For most consumer machines in the ~$500 range, I would expect to put in a lot of time leveling the bed and working about your part lifting during the print.

As far as materials go, there are a lot of options. PLA is simple to print and does not require a heated bed but is not as durable as the other materials. ABS is strong but requires a heated bed and tends to have shrinkage/warping problems, so you have to design accordingly. Polycarbonate is impact resistant and strong but requires a nozzle that can print at over 300 C. Nylon is tough and would also be a good option but also requires higher nozzle temperatures. There are many other materials, these are just some of the common ones.

I think printing is definitely worth the time. I recently checked how much one of my 3" tops would cost through Shapeways. They quoted me over $200 for an ABS print. I think my machine is paying for it's self each time I make a top.

Re: 3D Printed Top

So I haven't been following along since nationals.. AWESOME work

I hope the tips come out well from emachineshop, their tolerances are notoriously bad.. but for a tip it may not matter very much.

If there is serious interest in having tips made in quantity I can do it pretty cheap.. I'd have to have a decided up design that everybody wants. If there is interest in 100+ I'd just have one of my shops I work with do it, they're very cheap. Steel is a bit more, but that's mostly just material cost.. the time doesn't change much on a big cnc.

You should experiment with PETG. It does require a bit slower print times, but it prints like PLA with all the strength of ABS.. so like an abs that isn't a nightmare to print long prints with. They have some beautiful translucent petg too. (it goes under a number of different names now)

I hope the tips come out well from emachineshop, their tolerances are notoriously bad.. but for a tip it may not matter very much.

If there is serious interest in having tips made in quantity I can do it pretty cheap.. I'd have to have a decided up design that everybody wants. If there is interest in 100+ I'd just have one of my shops I work with do it, they're very cheap. Steel is a bit more, but that's mostly just material cost.. the time doesn't change much on a big cnc.

You should experiment with PETG. It does require a bit slower print times, but it prints like PLA with all the strength of ABS.. so like an abs that isn't a nightmare to print long prints with. They have some beautiful translucent petg too. (it goes under a number of different names now)

Re: 3D Printed Top

Thanks kyo,

I have been busy since nationals as you can see.

I have used emachineshop for other simple items and have been happy. I think I would trust them for a top tip. Next time I am thinking of ordering I will check with you first.

Next time I buy material I will definitely buy some PETG. I have read good things about it and the colors are neat.

I have been busy since nationals as you can see.

I have used emachineshop for other simple items and have been happy. I think I would trust them for a top tip. Next time I am thinking of ordering I will check with you first.

Next time I buy material I will definitely buy some PETG. I have read good things about it and the colors are neat.

Re: 3D Printed Top

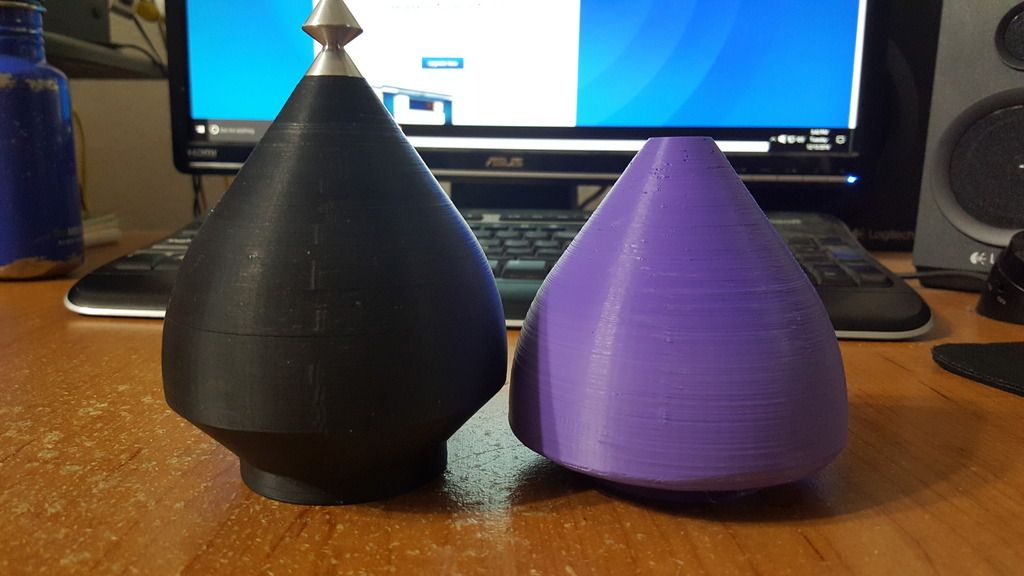

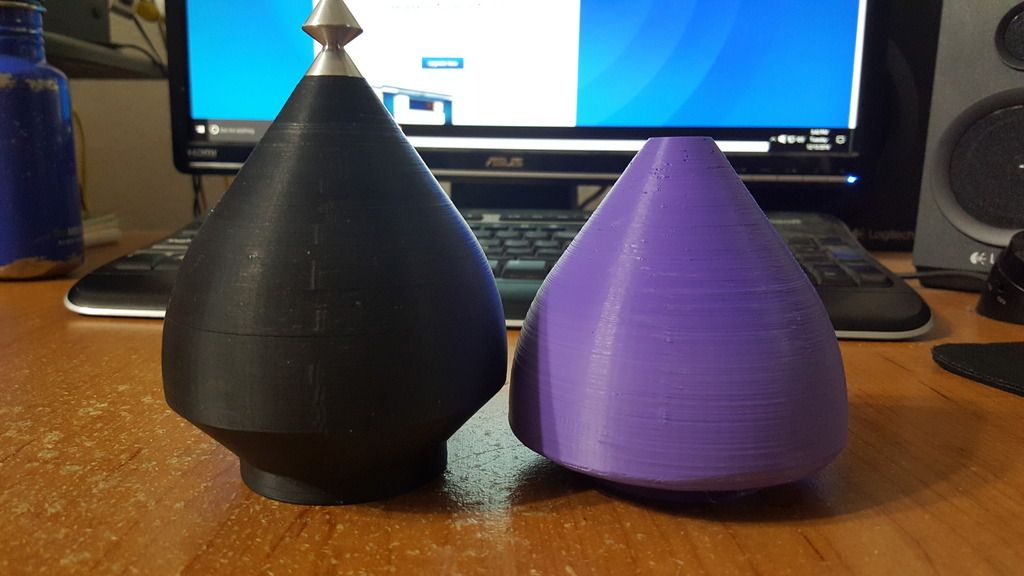

So I have been working at improving my 3D printed tops. I have been working on a 3.5" diameter size. I think I have had a break through that is worth mentioning. By making my shoulder a 45 degree slope, I have made it possible for the machine to print without support material. This has allowed for a smooth looking shoulder area. I will be experimenting with this more but figured it was worth an update. The pictures below compare the different designs that I have been playing with.

It plays great to boot

It plays great to boot

- dazzlingdave

- ITSA

- Posts: 225

- Joined: Sat Oct 27, 2012 6:28 pm

- Contact:

- the Earl of Whirl

- ITSA

- Posts: 8,196

- Joined: Sat Jul 04, 2009 12:41 pm

- Contact: